O Guia Completo do cacao mucilage

Descubra a superfruta escondida dentro de cada fruto de cacau - um suco translúcido com propriedades nutricionais notáveis

O Que É o cacao mucilage?

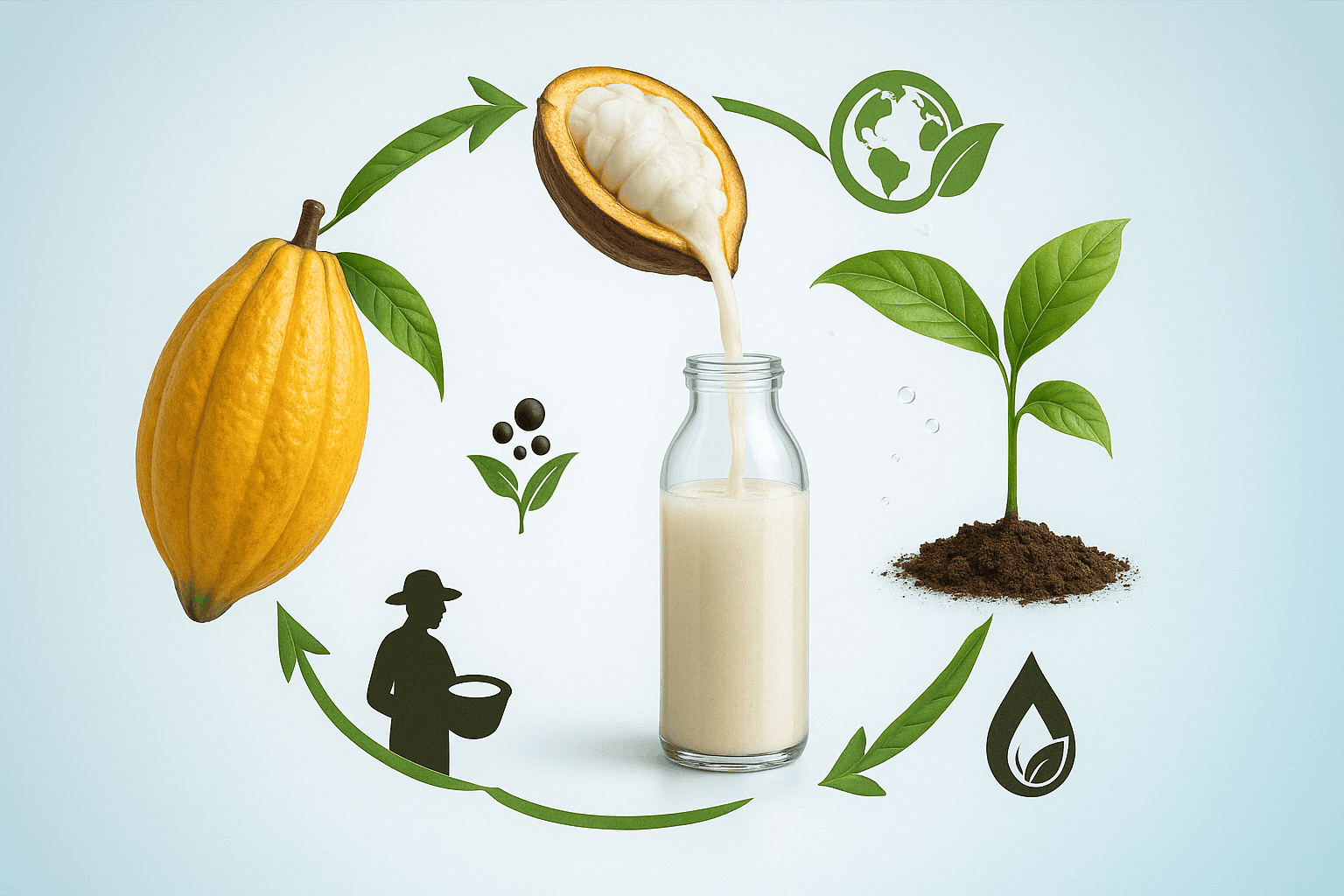

O cacao mucilage é a polpa doce e ácida que envolve naturalmente os grãos de cacau dentro do fruto. Esta substância translúcida e gelatinosa representa cerca de 40% do fruto de cacau, mas por séculos foi descartada como resíduo durante a produção de chocolate.

Rico em açúcares naturais, vitaminas e poderosos antioxidantes, o cacao mucilage possui um perfil de sabor de fruta tropical completamente diferente do chocolate. Enquanto os grãos são fermentados e processados em cacau, o mucilage pode ser prensado em um suco refrescante que tem gosto de uma mistura de lichia, uva branca e cítricos.

Análises científicas recentes revelaram que o cacao mucilage contém 105,08 mg GAE/100mL de polifenóis - superior a muitas superfrutas celebradas. Esta descoberta, combinada com sua doçura natural de 14-18 Brix e compostos benéficos como a teobromina, posicionou o cacao mucilage como um ingrediente emergente para bebidas funcionais.

Análise Científica

Como Difere do Chocolate

Embora ambos venham do mesmo fruto de cacau, o mucilage e os grãos de chocolate servem propósitos muito diferentes. Entender suas diferenças ajuda a explicar não apenas como o chocolate é feito, mas também por que o cacao mucilage ganhou atenção como ingrediente alimentício e para bebidas por si só.

Um fruto de cacau contém várias partes, mas duas se destacam. Os grãos, que representam cerca de 20% do peso do fruto, são a matéria-prima para o chocolate. O mucilage, uma polpa translúcida e gelatinosa que envolve os grãos, representa quase 40% do fruto. Tradicionalmente, o mucilage foi descartado ou usado apenas durante a fermentação. Novas pesquisas e métodos de processamento mostram que ele tem valor nutricional e sensorial significativo além desse papel.

Papel na Fermentação:

O mucilage desempenha um papel crítico no desenvolvimento do sabor do chocolate. Durante a fermentação, os açúcares e ácidos no mucilage se decompõem, gerando calor e desencadeando mudanças bioquímicas nos grãos. Sem esta etapa, os grãos de cacau permaneceriam amargos e subdesenvolvidos. No entanto, a maior parte do próprio mucilage é drenada no processo, raramente consumida diretamente até recentemente.

Diferenças Nutricionais:

A composição nutricional do mucilage difere da dos grãos. Enquanto os grãos são ricos em gordura (cerca de 50-55%) e precursores de compostos como teobromina e cafeína, o mucilage é rico em água, açúcares simples, vitamina C e polifenóis. A análise laboratorial mostrou que o mucilage contém 105,08 mg de equivalentes de ácido gálico (GAE) por 100 mL de polifenóis. Isso é superior a muitos sucos de frutas comumente promovidos pelo conteúdo antioxidante. Seu sabor reflete este perfil: leve, com notas cítricas e caráter de fruta tropical. Os grãos, por outro lado, oferecem profundidade através de sabores torrados, de nozes e chocolate uma vez processados.

Usos Comerciais:

Os grãos seguem um longo caminho: fermentação, secagem, torrefação, moagem e conchagem, eventualmente se tornando massa de cacau, manteiga de cacau e cacau em pó. O mucilage pode ser prensado em suco, concentrado ou seco em pós para bebidas, doces e aplicações nutracêuticas. A comparação ressalta a diferença entre suco de cacau e cacau: um é refrescante, translúcido e frutado; o outro denso, rico e sólido.

cacao mucilage vs Grãos de Cacau (Chocolate)

| Categoria | cacao mucilage | Grãos de Cacau (Chocolate) |

|---|---|---|

| Localização da fonte no fruto | Polpa gelatinosa translúcida envolvendo os grãos (≈40% do fruto) | Sementes dentro da cavidade do fruto (≈20% do fruto) |

| Método de processamento | Prensagem ou evaporação em suco/pó; etapas mínimas | Fermentação → secagem → torrefação → moagem |

| Destaques nutricionais | 105,08 mg GAE/100 mL polifenóis, vitamina C, açúcares naturais | 50-55% gordura, proteína, teobromina, cafeína |

| Usos comerciais principais | Suco, bebidas, pós, starter de fermentação | Chocolate, manteiga de cacau, cacau em pó |

| Perfil de sabor | Leve, notas cítricas, fruta tropical, refrescante | Rico, torrado, de nozes, amargo até ser adoçado |

Do Fruto à Garrafa: Processo Completo

Seleção e Colheita do Fruto

Os agricultores colhem os frutos a cada 20 dias, baseando-se em indicadores de maturação, como mudanças de cor e ressonância do fruto. A colheita manual previne ferimentos que convidariam o crescimento microbiano. A coleta deve ocorrer dentro de uma janela de dois dias para manter a qualidade. Um primeiro ponto de controle acontece aqui: frutos danificados ou imaturos são excluídos para garantir suco consistente. Este controle inicial faz parte da conformidade HACCP, preparando o cenário para extração segura. Ao focar na qualidade do fruto desde o início, os agricultores melhoram tanto o sabor quanto o rendimento, com média de 30-50 mL de mucilage por fruto.

Abertura do Fruto e Extração do Mucilage

Os trabalhadores abrem os frutos em lonas plásticas limpas para evitar contato com o solo. Dentro, os grãos estão cobertos com mucilage translúcido e gelatinoso. Usando facões ou porretes de madeira, os frutos são partidos e a massa é colhida em baldes plásticos limpos sem furos. Técnicas de separação mecânica, como peneiras vibratórias, ajudam a otimizar as taxas de rendimento, garantindo que pouco mucilage seja desperdiçado. Nesta etapa, o tempo é crítico: o mucilage deve ser extraído e coletado dentro de horas para preservar a frescura. A técnica adequada reduz o risco de contaminação e melhora a eficiência geral do processo de produção de cacao mucilage.

Separação Inicial e Drenagem

A massa extraída é transportada em sacos revestidos de plástico para evitar vazamento. Sacos laranja ou lonas vermelhas são frequentemente usados para auxiliar a drenagem enquanto distinguem visualmente os lotes. Os trabalhadores aplicam pressão virando a massa em cestos, ajudando a liberar mais líquido da polpa. Esta etapa permite que o mucilage se separe naturalmente dos grãos antes de uma filtragem mais fina. A drenagem eficiente garante maior recuperação sem comprometer a qualidade. Como cada fruto contribui com apenas 30-50 mL, a atenção aos detalhes importa. Ao final desta etapa, o mucilage começa a se parecer com o suco translúcido destinado à coleta.

Filtragem e Coleta

Em seguida, placas de coleta são posicionadas para receber o mucilage drenante. O líquido passa por funis e peneiras de malha, removendo a polpa residual enquanto retém nutrientes. Este é o segundo ponto de controle de qualidade: os trabalhadores verificam a clareza, checam material estranho e garantem que os recipientes estejam higienizados. A filtragem adequada equilibra limpeza com preservação de nutrientes, mantendo os antioxidantes intactos. O mucilage permanece leve, com aroma cítrico e tropical nesta etapa. A separação limpa previne deterioração posterior e fornece uma base confiável para engarrafamento. A filtragem garante que o suco seja adequado tanto para consumo direto quanto para uso como starter de fermentação no chocolate.

Teste de Qualidade

Antes do armazenamento, os lotes passam por verificações laboratoriais. Os técnicos medem os níveis de Brix para confirmar o teor de açúcar, pH para rastrear a acidez e amostras microbiológicas para verificar a segurança. Os testes consistentes garantem que o mucilage atenda aos padrões de qualidade alimentar e se alinhe aos requisitos HACCP. Variações de Brix ou pH indicam tempo de colheita impróprio ou contaminação. Medidas corretivas são aplicadas antes do congelamento para evitar perda de qualidade. Esses testes constroem rastreabilidade e confirmam que cada litro de suco de cacau mantém suas propriedades antioxidantes enquanto atende rigorosos padrões de bebidas para mercados locais e de exportação.

Congelamento e Armazenamento

O mucilage limpo é congelado imediatamente após os testes. O congelamento bloqueia sabor e nutrição, estendendo a vida útil. O armazenamento é mantido entre 4-8 °C para manuseio refrigerado, ou em temperaturas mais baixas quando congelado profundamente. Este é o ponto de controle de qualidade final: os recipientes são inspecionados quanto a vedações e rotulagem adequadas. Da colheita ao armazenamento, o cronograma nunca excede 48 horas, garantindo frescor. Uma vez pronto para engarrafamento, o mucilage congelado é descongelado, pasteurizado e envasado a quente diretamente da pasteurização. Essas etapas preservam a segurança enquanto mantêm o suco fiel ao seu sabor tropical e cítrico.

A Experiência de Sabor

Primeiras Impressões de Sabor

Para muitas pessoas, o primeiro gole de cacao mucilage é inesperado. O suco aparece como um âmbar pálido, quase ouro translúcido, com corpo leve. No paladar, entrega acidez brilhante semelhante a cítricos, equilibrada por uma doçura suave. Com 14-18 Brix, seus açúcares naturais dão um sabor limpo e refrescante sem peso. Diferente do caráter profundo e torrado do chocolate, o mucilage é vivo e frutado, mais próximo de suco tropical do que sobremesa. Servido gelado a 4-6 °C, parece fresco e revitalizante, tornando a experiência sensorial distinta de qualquer coisa associada ao cacau.

Análise das Notas de Sabor

O perfil de sabor do suco de cacau combina elementos de frutas tropicais e familiares. Sua acidez brilhante lembra tangerina ou lima, enquanto sua doçura delicada é reminiscente de uva branca ou lichia. Notas florais sutis suavizam a borda cítrica, criando uma experiência em camadas. Diferente de bebidas de frutas processadas, seu caráter parece fresco e inalterado, com uma doçura persistente que desaparece suavemente em vez de enjoar. Este equilíbrio de açúcar e acidez o torna versátil: agradável de beber sozinho, mas estruturado o suficiente para misturar com outros ingredientes. O resultado é um sabor que surpreende e satisfaz sem ser avassalador.

Textura e Sensação na Boca

O cacao mucilage tem uma textura sedosa que reveste a língua levemente antes de desaparecer. Sua viscosidade é ligeiramente mais grossa que a água, dando-lhe uma sensação suave sem ficar xaroposa. A origem gelatinosa do suco é perceptível em seu corpo, mas refinada através de filtragem cuidadosa. Esta sensação na boca realça sua impressão frutada, apoiando tanto o gole casual quanto o uso em aplicações culinárias.

Sugestões de Serviço e Harmonizações

Melhor apreciado gelado a 4-6°C, o cacao mucilage é versátil e funciona em múltiplos contextos. Combina bem com água com gás para um spritzer leve, mistura-se suavemente em coquetéis tropicais e adiciona doçura natural a smoothies sem necessidade de açúcar adicionado. Sua cor dourada translúcida também empresta apelo visual em copos transparentes. Com sua acidez brilhante e doçura equilibrada, nenhum aditivo artificial é necessário para apreciar seu perfil de sabor completo.

Condições de Serviço Ideais

Temperatura de serviço ideal

Brix (teor de açúcar natural)

Faixa de pH (acidez natural)

De Resíduo ao Bem-Estar

O Problema dos 70% de Resíduo

Por mais de 5.000 anos de cultivo de cacau, aproximadamente 70% de cada fruto de cacau era jogado fora. Enquanto os grãos eram valorizados pelo chocolate, o mucilage era visto como mero starter de fermentação, drenado e descartado após iniciar o processo.

Este resíduo criava desafios ambientais: acidificação do solo, atração de pragas e liberação de metano durante a decomposição. Nas regiões produtoras de cacau, os rios ficavam brancos com mucilage descartado durante a temporada de colheita, representando milhões de litros de nutrição desperdiçada.

A Descoberta Científica

Em 2019, pesquisadores suíços da ETH Zurique publicaram descobertas revolucionárias sobre o perfil nutricional do cacao mucilage. Sua análise revelou níveis de polifenóis superiores aos do açaí e da romã, reformulando como a indústria via este produto 'residual'.

- 3 vezes mais antioxidantes que suco de romã

- Fibras prebióticas naturais que apoiam a saúde intestinal

- Perfil completo de aminoácidos com nutrientes essenciais

- Alternativa sustentável aos adoçantes sintéticos

Reconhecimento Global

Até 2021, a FDA concedeu o status GRAS (Generally Recognized As Safe) ao cacao mucilage, abrindo mercados norte-americanos. A aprovação europeia de Novel Food seguiu em 2022, validando sua segurança e valor nutricional para o comércio internacional.

Hoje, o cacao mucilage está transformando a agricultura sustentável ao criar novas fontes de renda para agricultores. O que antes era resíduo agora comanda preços premium, com agricultores ganhando até 2,5 vezes mais por quilograma de cacau ao utilizar todo o fruto.

Referências e Leituras Complementares

A pesquisa sobre cacao mucilage está em andamento. Os dados apresentados são compilados de estudos publicados e relatórios da indústria.

Última Atualização: February 2026 |Para estudos específicos e citações, entre em contato: [email protected]