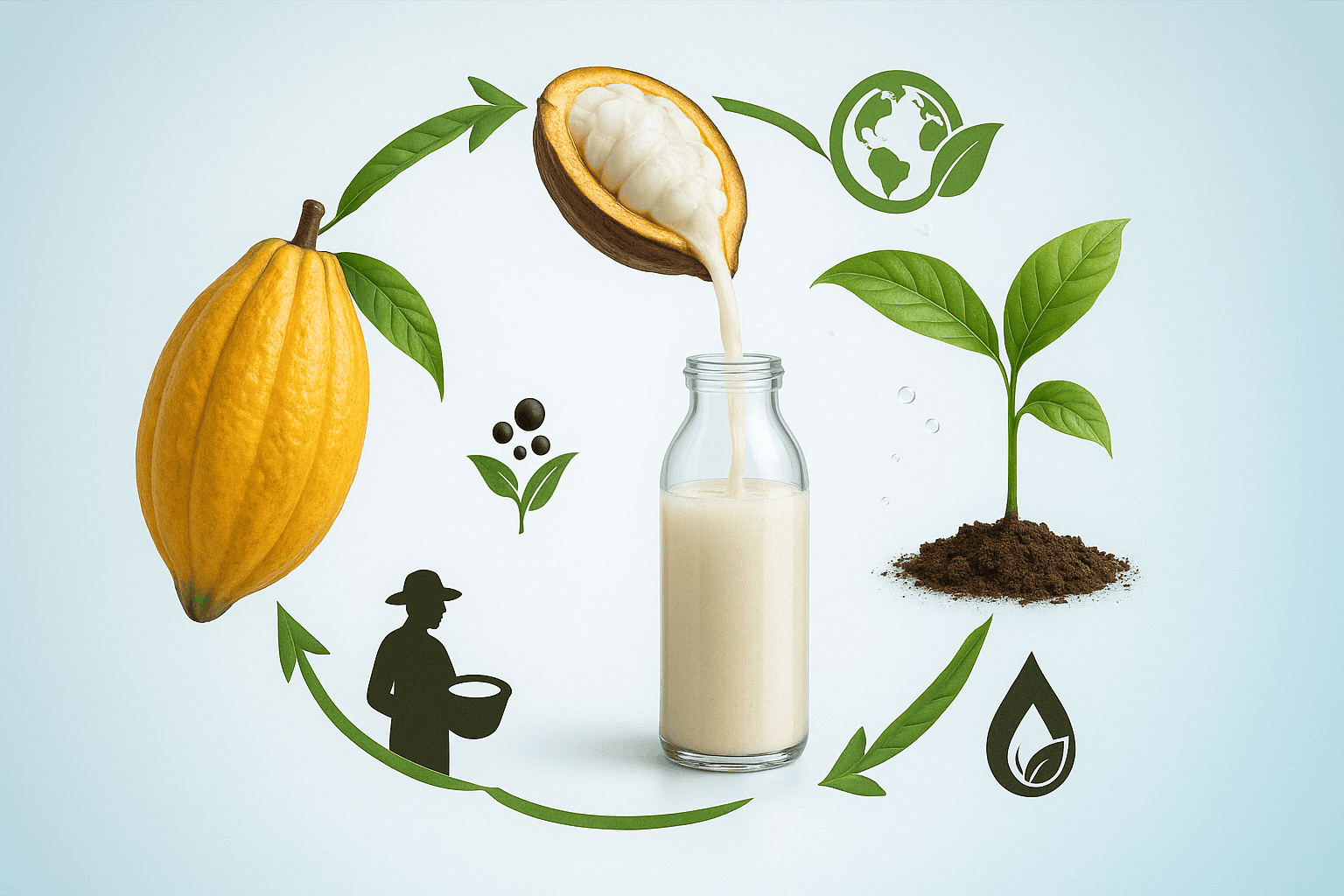

Le Guide Complet du Mucilage de Cacao

Découvrez le superfruit caché à l'intérieur de chaque cabosse de cacao - un jus translucide aux propriétés nutritionnelles remarquables

Qu'est-ce que le Mucilage de Cacao ?

Le mucilage de cacao est la pulpe sucrée et acidulée qui entoure naturellement les fèves de cacao à l'intérieur de la cabosse. Cette substance translucide et gélatineuse constitue environ 40% du fruit de cacao, pourtant pendant des siècles elle était jetée comme déchet pendant la production de chocolat.

Riche en sucres naturels, vitamines et puissants antioxydants, le mucilage de cacao a un profil de saveur de fruit tropical unique complètement différent du chocolat. Tandis que les fèves sont fermentées et transformées en cacao, le mucilage peut être pressé en un jus rafraîchissant qui goûte comme un mélange de litchi, raisin blanc et agrumes.

L'analyse scientifique récente a révélé que le mucilage de cacao contient 105.08 mg GAE/100mL de polyphénols - plus élevé que de nombreux superfruits célébrés. Cette découverte, combinée avec sa douceur naturelle à 14-18 Brix et des composés bénéfiques comme la théobromine, a positionné le mucilage de cacao comme un ingrédient émergent de boisson fonctionnelle.

Analyse Scientifique

Comment Il Diffère du Chocolat

Bien que tous deux proviennent de la même cabosse de cacao, le mucilage et les fèves de chocolat servent des objectifs très différents. Comprendre leurs différences aide à expliquer non seulement comment le chocolat est fait, mais aussi pourquoi le mucilage de cacao a gagné l'attention comme ingrédient alimentaire et de boisson à part entière.

Une cabosse de cacao contient plusieurs parties, mais deux se distinguent. Les fèves, qui constituent environ 20% du poids de la cabosse, sont la matière première pour le chocolat. Le mucilage, une pulpe translucide et gélatineuse qui entoure les fèves, représente près de 40% de la cabosse. Traditionnellement, le mucilage a été jeté ou utilisé seulement pendant la fermentation. De nouvelles recherches et méthodes de traitement montrent qu'il a une valeur nutritionnelle et sensorielle significative au-delà de ce rôle.

Rôle dans la Fermentation :

Le mucilage joue un rôle critique dans le développement de la saveur du chocolat. Pendant la fermentation, les sucres et acides dans le mucilage se décomposent, générant de la chaleur et déclenchant des changements biochimiques dans les fèves. Sans cette étape, les fèves de cacao resteraient amères et non développées. Pourtant, la plupart du mucilage lui-même est drainé dans le processus, rarement consommé directement jusqu'à récemment.

Différences Nutritionnelles :

La composition nutritionnelle du mucilage diffère de celle des fèves. Tandis que les fèves sont riches en graisse (environ 50–55%) et précurseurs de composés comme la théobromine et la caféine, le mucilage est riche en eau, sucres simples, vitamine C et polyphénols. L'analyse de laboratoire a montré que le mucilage contient 105.08 mg d'équivalents d'acide gallique (GAE) par 100 mL de polyphénols. C'est plus élevé que de nombreux jus de fruits communément promus pour leur contenu antioxydant. Sa saveur reflète ce profil : léger, avec des notes d'agrumes et un caractère de fruit tropical. Les fèves, d'autre part, livrent de la profondeur à travers des saveurs grillées, de noix et de chocolat une fois transformées.

Utilisations Commerciales :

Les fèves suivent un long chemin : fermentation, séchage, torréfaction, broyage et conchage, devenant finalement liqueur de chocolat, beurre de cacao et poudre de cacao. Le mucilage peut être pressé en jus, concentré ou séché en poudres pour boissons, confiseries et applications nutraceutiques. La comparaison souligne la différence entre jus de cacao et cacao : l'un est rafraîchissant, translucide et fruité ; l'autre dense, riche et solide.

Mucilage de Cacao vs Fèves de Cacao (Chocolat)

| Catégorie | Mucilage de Cacao | Fèves de Cacao (Chocolat) |

|---|---|---|

| Emplacement source dans la cabosse | Pulpe gélatineuse translucide entourant les fèves (≈40% de la cabosse) | Graines à l'intérieur de la cavité de la cabosse (≈20% de la cabosse) |

| Méthode de traitement | Pressage ou évaporation en jus/poudre ; étapes minimales | Fermentation → séchage → torréfaction → broyage |

| Points nutritionnels saillants | 105.08 mg GAE/100 mL polyphénols, vitamine C, sucres naturels | 50–55% graisse, protéine, théobromine, caféine |

| Utilisations commerciales principales | Jus, boissons, poudres, starter de fermentation | Chocolat, beurre de cacao, poudre de cacao |

| Profil de saveur | Léger, notes d'agrumes, fruit tropical, rafraîchissant | Riche, grillé, de noix, amer jusqu'à édulcoré |

De la Cabosse à la Bouteille : Processus Complet

Sélection et Récolte des Cabosses

Les agriculteurs récoltent les cabosses tous les 20 jours, s'appuyant sur des indicateurs de maturité, tels que les changements de couleur et la résonance de la cabosse. La récolte manuelle prévient les blessures qui inviteraient la croissance microbienne. La collecte doit se produire dans une fenêtre de deux jours pour maintenir la qualité. Un premier point de contrôle se produit ici : les cabosses endommagées ou pas assez mûres sont exclues pour assurer un jus cohérent. Ce contrôle initial fait partie de la conformité HACCP, préparant le terrain pour une extraction sûre. En se concentrant sur la qualité de la cabosse dès le début, les agriculteurs améliorent à la fois la saveur et le rendement, moyennant 30–50 mL de mucilage par cabosse.

Ouverture des Cabosses et Extraction du Mucilage

Les travailleurs ouvrent les cabosses sur des bâches plastiques propres pour éviter le contact avec le sol. À l'intérieur, les fèves sont enrobées de mucilage translucide et gélatineux. Utilisant des machettes ou des massues en bois, les cabosses sont fendues, et la masse est ramassée dans des seaux plastiques propres sans trous. Les techniques de séparation mécanique comme les tamis vibrants aident à optimiser les taux de rendement, s'assurant que peu de mucilage soit gaspillé. À cette étape, le timing est critique : le mucilage doit être extrait et collecté dans les heures pour préserver la fraîcheur. La technique appropriée réduit le risque de contamination et améliore l'efficacité globale du processus de production de mucilage de cacao.

Séparation Initiale et Drainage

La masse extraite est transportée dans des sacs doublés de plastique pour prévenir les fuites. Des sacs orange ou des bâches rouges sont souvent utilisés pour aider au drainage tout en distinguant visuellement les lots. Les travailleurs appliquent une pression en tournant la masse dans des paniers, aidant à libérer plus de liquide de la pulpe. Cette étape permet au mucilage de se séparer naturellement des fèves avant une filtration plus fine. Un drainage efficace assure une récupération plus élevée sans compromettre la qualité. Parce que chaque cabosse ne contribue que 30–50 mL, l'attention aux détails compte. À la fin de cette étape, le mucilage commence à ressembler au jus translucide destiné à la collecte.

Filtrage et Collecte

Ensuite, des plaques de collecte sont positionnées pour recevoir le mucilage qui s'égoutte. Le liquide passe à travers des entonnoirs et des passoires à mailles, enlevant la pulpe résiduelle tout en retenant les nutriments. C'est le deuxième point de contrôle qualité : les travailleurs vérifient la clarté, contrôlent le matériel étranger et s'assurent que les contenants sont désinfectés. Une filtration appropriée équilibre propreté avec préservation des nutriments, gardant les antioxydants intacts. Le mucilage reste léger, parfumé aux agrumes et tropical à cette étape. Une séparation propre prévient la détérioration ultérieure et fournit une base fiable pour la mise en bouteille. La filtration assure que le jus convient à la fois pour la consommation directe et l'utilisation comme starter de fermentation dans le chocolat.

Tests de Qualité

Avant le stockage, les lots subissent des vérifications de laboratoire. Les techniciens mesurent les niveaux de Brix pour confirmer la teneur en sucre, le pH pour suivre l'acidité, et des échantillons microbiologiques pour vérifier la sécurité. Des tests cohérents garantissent que le mucilage répond aux normes de qualité alimentaire et s'aligne avec les exigences HACCP. Les variations de Brix ou pH indiquent soit un timing de récolte inapproprié soit une contamination. Des mesures correctives sont appliquées avant la congélation pour prévenir la perte de qualité. Ces tests construisent la traçabilité et confirment que chaque litre de jus de cacao maintient ses propriétés antioxydantes tout en respectant les normes strictes de boissons pour les marchés locaux et d'exportation.

Congélation et Stockage

Le mucilage propre est congelé immédiatement après les tests. La congélation verrouille la saveur et la nutrition, prolongeant la durée de conservation. Le stockage est maintenu entre 4–8 °C pour la manipulation réfrigérée, ou à des températures plus basses quand congelé profondément. C'est le point de contrôle qualité final : les contenants sont inspectés pour des joints appropriés et l'étiquetage. De la récolte au stockage, la chronologie ne dépasse jamais 48 heures, assurant la fraîcheur. Une fois prêt pour la mise en bouteille, le mucilage congelé est décongelé, pasteurisé et rempli à chaud directement depuis la pasteurisation. Ces étapes préservent la sécurité tout en gardant le jus fidèle à sa saveur tropicale et citronnée.

L'Expérience Gustative

Premières Impressions Gustatives

Pour beaucoup de gens, la première gorgée de mucilage de cacao est inattendue. Le jus apparaît comme un ambre pâle, presque doré translucide, avec un corps léger. Au palais, il délivre une acidité brillante similaire aux agrumes, équilibrée par une douceur douce. À 14–18 Brix, ses sucres naturels donnent un goût propre et rafraîchissant sans lourdeur. Contrairement au caractère profond et grillé du chocolat, le mucilage est vif et orienté fruit, plus proche du jus tropical que du dessert. Servi frais à 4–6 °C, il se sent croquant et revitalisant, rendant l'expérience sensorielle distincte de tout ce qui est associé au cacao.

Analyse des Notes de Saveur

Le profil de saveur du jus de cacao combine des éléments de fruits tropicaux et familiers. Son acidité brillante rappelle la mandarine ou le citron vert, tandis que sa douceur délicate évoque le raisin blanc ou le litchi. Des nuances florales subtiles adoucissent le bord citronné, créant une expérience en couches. Contrairement aux boissons aux fruits transformées, son caractère se sent frais et non altéré, avec une douceur persistante qui s'estompe doucement plutôt qu'écœurante. Cet équilibre de sucre et d'acidité le rend polyvalent : agréable à boire seul, mais assez structuré pour se mélanger avec d'autres ingrédients. Le résultat est une saveur qui surprend et satisfait sans être accablante.

Texture et Sensation en Bouche

Le mucilage de cacao a une texture soyeuse qui enrobe légèrement la langue avant de disparaître. Sa viscosité est légèrement plus épaisse que l'eau, donnant une sensation lisse sans devenir sirupeuse. L'origine gélatineuse du jus est perceptible dans son corps mais raffinée par une filtration soigneuse. Cette sensation en bouche améliore son impression orientée fruit, soutenant à la fois la dégustation décontractée et l'utilisation dans les applications culinaires.

Suggestions de Service et Accords

Mieux apprécié frais à 4–6°C, le mucilage de cacao est polyvalent et fonctionne dans de multiples contextes. Il se marie bien avec l'eau pétillante pour un spritzer léger, se mélange en douceur dans les cocktails tropicaux, et ajoute une douceur naturelle aux smoothies sans besoin de sucre ajouté. Sa couleur dorée translucide prête aussi un attrait visuel dans la verrerie transparente. Avec son acidité brillante et sa douceur équilibrée, aucun additif artificiel n'est nécessaire pour apprécier son profil de saveur complet.

Conditions de Service Optimales

Température de service optimale

Brix (teneur en sucre naturel)

Plage de pH (acidité naturelle)

Du Déchet au Bien-être

Le Problème des 70% de Déchets

Pendant plus de 5 000 ans de culture du cacao, environ 70% de chaque cabosse de cacao était jetée. Tandis que les fèves étaient chéries pour le chocolat, le mucilage était vu comme un simple starter de fermentation, drainé et jeté après avoir initié le processus.

Ce déchet créait des défis environnementaux : acidifiant les sols, attirant les parasites, et libérant du méthane en se décomposant. Dans les régions productrices de cacao, les rivières coulaient blanches avec le mucilage jeté pendant la saison de récolte, représentant des millions de litres de nutrition gaspillée.

La Percée Scientifique

En 2019, des chercheurs suisses à l'ETH Zürich ont publié des découvertes révolutionnaires sur le profil nutritionnel du mucilage de cacao. Leur analyse a révélé des niveaux de polyphénols dépassant l'açaí et la grenade, remodelant comment l'industrie voyait ce produit de 'déchet'.

- 3x plus d'antioxydants que le jus de grenade

- Fibres prébiotiques naturelles soutenant la santé intestinale

- Profil complet d'acides aminés avec nutriments essentiels

- Alternative durable aux édulcorants synthétiques

Reconnaissance Mondiale

En 2021, la FDA a accordé le statut GRAS (Généralement Reconnu Comme Sûr) au mucilage de cacao, ouvrant les marchés nord-américains. L'approbation d'Aliment Nouveau Européen a suivi en 2022, validant sa sécurité et sa valeur nutritionnelle pour le commerce international.

Aujourd'hui, le mucilage de cacao transforme l'agriculture durable en créant de nouveaux flux de revenus pour les agriculteurs. Ce qui était autrefois un déchet commande maintenant des prix premium, avec des agriculteurs gagnant jusqu'à 2,5x plus par kilogramme de cacao en utilisant toute la cabosse.

Références et Lectures Complémentaires

La recherche sur le mucilage de cacao est en cours. Les données présentées sont compilées à partir d'études publiées et de rapports de l'industrie.

Dernière Mise à Jour: février 2026 |Pour des études spécifiques et des citations, contactez: [email protected]